¿Qué es el proceso de envasado automatizado?

En el panorama en rápida evolución de la fabricación moderna, la eficiencia y la precisión se han vuelto primordiales. Un aspecto crucial que contribuye significativamente a lograr estos objetivos es el proceso de envasado automatizado. Esta revolucionaria estrategia de embalaje no sólo aumenta la producción sino que también asegura uniformidad y precisión en el producto final. En este artículo, profundizaremos en los componentes clave y los beneficios del proceso de envasado automatizado, arrojando luz sobre su importancia en el panorama industrial actual.

Definición del proceso de envasado automatizado

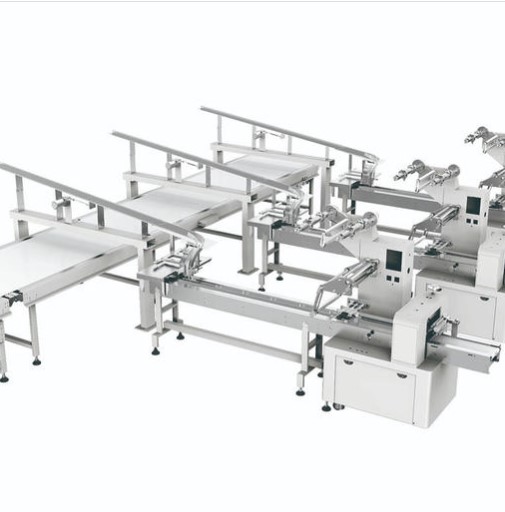

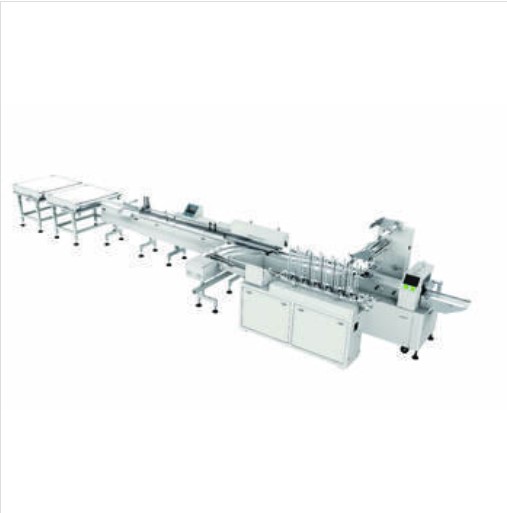

El proceso de embalaje automatizado implica el uso de maquinaria y tecnología modernas para realizar diferentes operaciones de embalaje sin participación humana directa. Este proceso abarca una variedad de actividades, desde el llenado y sellado hasta el etiquetado y paletizado, todas ejecutadas a la perfección mediante sistemas automatizados. El objetivo principal es optimizar la línea de envasado, reducir el error humano y mejorar la eficiencia operativa general.

Componentes clave del embalaje automatizado

A continuación se muestran algunos componentes clave del embalaje automatizado:

Sistemas de llenado

Los sistemas de llenado automatizados miden y dispensan adecuadamente la cantidad requerida de producto en contenedores de embalaje. Estos sistemas pueden manejar una amplia gama de viscosidades y consistencias de productos, asegurando llenados precisos y consistentes.

Máquinas de Sellado y Cerrado

Las máquinas de sellado y cierre utilizan tecnología avanzada para sellar paquetes de forma segura. Al utilizar termosellado, sellado con pegamento u otros métodos, estos dispositivos garantizan un embalaje hermético y a prueba de manipulaciones.

Equipo de etiquetado

Las etiquetadoras automáticas aplican etiquetas con rapidez y precisión, asegurando que cada producto esté correctamente identificado. Estos sistemas pueden manejar una variedad de tipos y tamaños de etiquetas, lo que da como resultado una apariencia limpia y profesional.

Robots paletizadores

En las instalaciones de fabricación a gran escala, los robots paletizadores asumen la tarea de disponer los productos terminados en palés. Estos robots apiladores mejoran la operación, asegurando la estabilidad durante el tránsito y el almacenamiento.

Sistemas de control de calidad

Las líneas de envasado automatizadas a menudo incorporan sistemas de control de calidad, como sensores y cámaras, para inspeccionar los productos en busca de defectos. Esto contribuye a mantener altos estándares y reduce la posibilidad de que lleguen a los clientes envases de calidad inferior.

Beneficios del embalaje automatizado

Eficiencia incrementada

La automatización no sólo acelera el proceso de embalaje sino que también permite un funcionamiento continuo, lo que reduce el tiempo de inactividad causado por el trabajo manual. El resultado son mayores tasas de producción, mayor rendimiento y la capacidad de satisfacer eficazmente las crecientes demandas del mercado.

Consistencia y precisión

Los sistemas automatizados, por definición, realizan trabajos con un grado de precisión que es difícil de imitar manualmente. La consistencia y precisión que ofrece la automatización minimizan las variaciones en la calidad del empaque, reduciendo la necesidad de retrabajo y asegurando que cada producto cumpla con los estándares establecidos.

Ahorro de costes

Si bien la inversión inicial en equipos de envasado automatizados es elevada, las ventajas a largo plazo se traducen en importantes reducciones de costes. Los costos laborales reducidos, las tasas de error más bajas y la mayor eficiencia general contribuyen a un retorno positivo de la inversión a lo largo del tiempo.

Adaptabilidad y escalabilidad

La adaptabilidad de los sistemas de embalaje automatizados permite a los fabricantes adaptarse fácilmente a cambios en los tipos de productos, formatos de embalaje o volúmenes de producción. Gracias a su escalabilidad, las organizaciones pueden adaptarse rápidamente a los cambios del mercado y a las cambiantes demandas de los clientes.

Conclusión

El proceso de embalaje automatizado es un testimonio de la evolución continua de las prácticas de fabricación. Como proveedor líder de máquinas empacadoras , Soontrue se dedica a ofrecer una amplia gama de máquinas empacadoras que incluyen máquinas empacadoras automáticas , máquinas empacadoras de envoltura fluida , máquinas empacadoras horizontales , etc. Si está interesado en ellas, no dude en navegar por nuestro sitio web para obtener más información. ¡Detalles de producto!

Preguntas frecuentes

P1: ¿Cómo mejora el embalaje automatizado la eficiencia en la fabricación? R: El embalaje automatizado mejora la eficiencia en la fabricación al agilizar todo el proceso de embalaje. Las tareas de llenado, sellado, etiquetado y paletizado se realizan con precisión y velocidad, minimizando el tiempo de inactividad y aumentando las tasas de producción generales. La ejecución consistente y precisa de estas tareas reduce la necesidad de intervención manual, lo que permite a los fabricantes satisfacer las crecientes demandas de manera eficiente.

P2: ¿Qué tipos de productos son adecuados para el envasado automatizado?

R: El embalaje automatizado es versátil y se puede adaptar a varios tipos de productos en todas las industrias. Es adecuado para una amplia gama de productos, incluidos, entre otros, líquidos, polvos, materiales granulares y productos sólidos. La flexibilidad de los sistemas automatizados permite a los fabricantes ajustar los parámetros para adaptarse a diferentes viscosidades, consistencias y formatos de envasado de productos.

P3: ¿Cómo contribuyen los sistemas de embalaje automatizados al ahorro de costes a largo plazo?

R: Si bien la inversión inicial en sistemas de embalaje automatizados puede ser significativa, los beneficios a largo plazo contribuyen a ahorros sustanciales de costos. Los procesos automatizados reducen los costos laborales al minimizar la necesidad de mano de obra, y la disminución de las tasas de error resulta en menos retrabajo y desperdicio. Además, la mayor eficiencia general de la línea de envasado tiene un impacto positivo en el retorno de la inversión a lo largo del tiempo.