¿Cómo funcionan los sistemas de embalaje automatizados?

En el acelerado panorama industrial actual, la eficiencia es primordial. Los fabricantes buscan constantemente soluciones innovadoras para optimizar sus procesos de producción y satisfacer las crecientes demandas de los consumidores. Entre estas opciones, los sistemas de embalaje automatizados se destacan como un componente clave de la producción contemporánea, ya que brindan velocidad, precisión y confiabilidad excepcionales. Pero, ¿cómo funcionan exactamente estos sofisticados sistemas?

Comprensión de los sistemas de embalaje automatizados

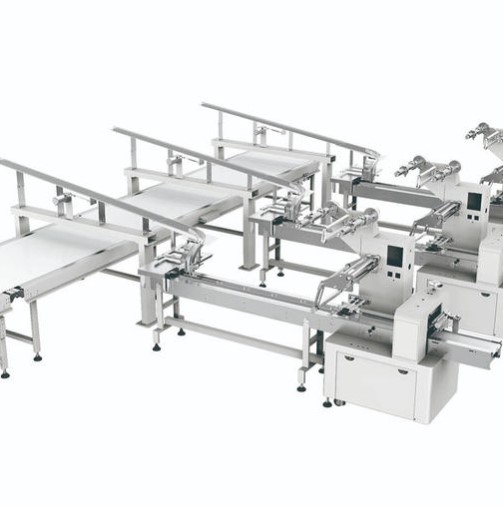

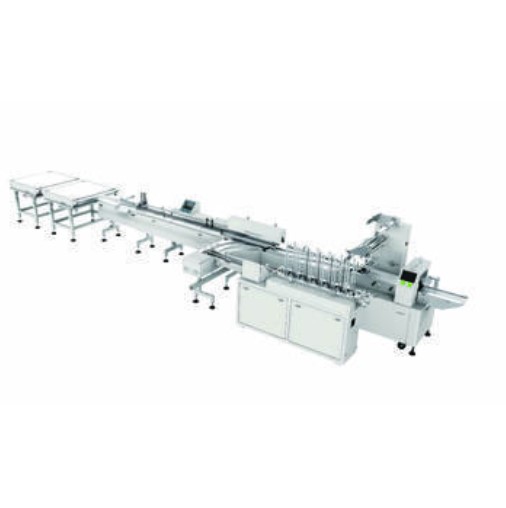

Los sistemas de embalaje automatizados representan la convergencia de tecnología de punta y automatización industrial.Estos sistemas están destinados a automatizar todo el proceso de envasado, desde la clasificación y disposición del producto hasta el sellado y el etiquetado, con poca interacción humana. Al aprovechar la robótica, los sensores y el software avanzado, optimizan la eficiencia, reducen los costos de mano de obra y garantizan una calidad constante del producto.

Componentes y tecnologías clave

Brazos robóticos: en el corazón de los sistemas de embalaje automatizados se encuentran los brazos robóticos equipados con pinzas o ventosas. Estos dispositivos adaptables pueden recoger, mover y posicionar objetos con precisión precisa, incluso en condiciones de alta velocidad.

Sistemas Transportadores: Cintas transportadoras o rodillos transportan los productos a través de diferentes etapas del proceso de empaque. Mantienen un flujo fluido y continuo de productos básicos, lo que aumenta el rendimiento y reduce el tiempo de inactividad.

Sistemas de visión: Los sensores y cámaras de visión juegan un papel importante en el control de calidad y la identificación de productos. Inspeccionan los artículos en busca de defectos, verifican la integridad del embalaje y guían las acciones robóticas con comentarios en tiempo real.

Maquinaria de embalaje: los sistemas automatizados integran diversas maquinarias de embalaje, como máquinas de formado, llenado y sellado (FFS), enfardadoras retráctiles y selladoras de cajas. Estos dispositivos manejan de manera precisa y eficiente tareas especializadas como embolsado, embalaje y sellado.

Software de control: Un software avanzado gestiona todo el proceso de embalaje, sincronizando los movimientos de robots, cintas transportadoras y máquinas. Optimiza el flujo de trabajo, ajusta los parámetros sobre la marcha y monitorea el rendimiento para garantizar un funcionamiento sin problemas.

El flujo de trabajo de los sistemas de embalaje automatizados

Este es el flujo de trabajo de los sistemas de embalaje automatizados:

Alimentación de productos: las materias primas o los productos terminados se introducen en el sistema, ya sea manualmente o mediante transportadores automatizados, y luego se clasifican y orientan para su embalaje.

Inspección de productos: los sistemas de visión inspeccionan cada artículo en busca de defectos, variaciones de tamaño u otros problemas de calidad. Los productos defectuosos se desvían para su posterior inspección o rechazo.

Selección de embalaje: el sistema determina los materiales de embalaje adecuados, como bolsas, cajas o contenedores, según las características del producto y los requisitos del pedido.

Proceso de embalaje: El proceso de embalaje se realiza mediante brazos robóticos o máquinas especializadas, que llenan contenedores, envuelven artículos y sellan paquetes de forma precisa y rápida.

Etiquetado y codificación: una vez envasados, los productos pueden someterse a etiquetado y codificación con fines de trazabilidad y cumplimiento. Los sistemas automatizados aplican etiquetas, imprimen códigos de lote e inspeccionan la legibilidad de los códigos de barras.

Inspección final y clasificación: los productos terminados se someten a una inspección final para garantizar que cumplan con los estándares de calidad. Se clasifican y envían para su almacenamiento, envío o procesamiento posterior.

Ventajas de los sistemas de embalaje automatizados

Mayor eficiencia y productividad: los sistemas de embalaje automatizados funcionan con una eficiencia notable, superando a menudo las capacidades del trabajo manual. Al reducir la interacción humana y mejorar la productividad, estos sistemas pueden manejar enormes cantidades de artículos con velocidad y precisión constantes.

Control de calidad mejorado: la coherencia es clave en las operaciones de embalaje, especialmente en industrias donde la integridad y seguridad del producto son primordiales. Las soluciones de embalaje automatizadas destacan por cumplir estrictos estándares de control de calidad al reducir la posibilidad de errores humanos.

Ahorro de costos: si bien la inversión inicial en sistemas de embalaje automatizados puede parecer sustancial, los ahorros de costos a largo plazo que ofrecen son significativos. Estas tecnologías reducen los gastos de mano de obra relacionados con los procesos de embalaje al eliminar la necesidad de mano de obra.

Flexibilidad y adaptabilidad: los sistemas de embalaje automatizados ofrecen una flexibilidad incomparable, lo que permite a los productores adaptar rápidamente los procesos de producción a nuevos productos, tipos de paquetes o necesidades de personalización.

Mejora de la seguridad en el lugar de trabajo: Las operaciones de embalaje manual pueden poner en peligro la seguridad de los trabajadores, incluidas lesiones por esfuerzos repetitivos, accidentes al manipular mercancías pesadas y exposición a productos químicos peligrosos. Los sistemas de embalaje automatizados ayudan a mitigar estos riesgos al minimizar la necesidad de mano de obra y reducir el contacto directo con maquinaria o materiales potencialmente peligrosos.

Conclusión

Los sistemas de embalaje automatizados representan un cambio de paradigma en la fabricación moderna y ofrecen eficiencia, precisión y escalabilidad incomparables.Si busca máquinas de envasado automatizadas, Soontrue es ideal para usted. Nos especializamos en ofrecer diversas máquinas de envasado automatizadas . ¡Elija nuestros productos y mejore la efectividad de su negocio ahora!